AUTOMATIC TRAY WASHER

LAV10

WITH MODULAR COMPOSITION – up to 600 trays/hour

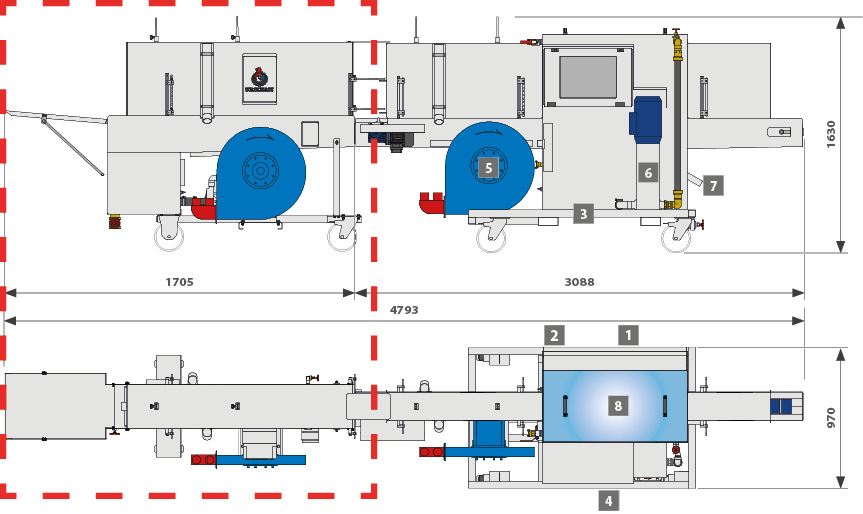

MACHINE DESCRIPTION - LAV10

The LAV10 automatically washes and disinfects trays and containers in general, of various shapes and sizes.

Once positioned at the entrance to the machine, the containers advance inside it automatically, by means of the support belt that runs on the bottom. In the washing chamber, the containers containers are water sprayed by high pressure nozzles: it can be easily removed to facilitate cleaning and, if necessary, for replacement.

After washing with water, the containers can move through an additional treatment to eliminate any pathogenic factors: they can be treated with chemicals, suitably diluted, or with UV lamps, capable of eliminating photosensitive bacteria. In both cases, all that is required is integration of the standard model with the treatment tunnel.

Additionally, when connected to an input feed belt and an output accumulation belt, the automatic tray-washer can be transformed into a complete and autonomous WASHING LINE, with great results in terms of production and efficiency.

TECHNICAL SPECIFICATIONS - LAV10

- Pressure wash.

- Flushing.

- Hot-galvanised steel base plate.

- Water filter with extractable drawer.

- Fan for trays drainage 2,2 kW.

- Stainless steel vertical multi-stage pump 3,7 kW.

- Discharge for overflowing.

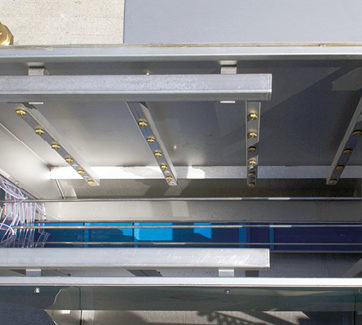

- Top plexiglass door for nozzles inspection.

- Tray washing system with removable nozzles, for an easier replacement.

- Water level control with float.

- Frame in AISI 304 stainless steel.

MAIN ACCESSORIES - LAV10

- Exit table for water draining.

- Wheels kit: nr. 4 turning stainless wheels diam. 200 mm.

- Water heating with electric resistance 8 kW.

- Tunnel for containers chemical treatment with antibacterial substances.

- Wheels kit: nr. 3 stainless wheels diam. 200 mm for chemical treatment tunnel.

- Second fan for accessory tunnel, to improve container drainage.

- Tunnel with UV lamps for the treatment of photosensitive bacteria.

- Feeding belt.

- Accumulation belt.

- Final stacking unit, with balance stacker.

OPERATING SYSTEM - LAV10

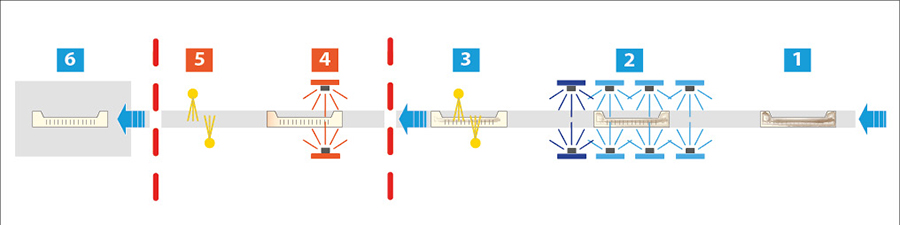

LAV10 with tunnel for chemical treatment:

- TRAYS ENTRY

- PRESSURE WASH WITH WATER FROM THE TANK + RINSE WITH CURRENT WATER

- TRAYS DRAINAGE

- DISINFECTION TREATMENT

- TRAYS DRAINAGE

- EXIT TABLE FOR WATER DRAINING

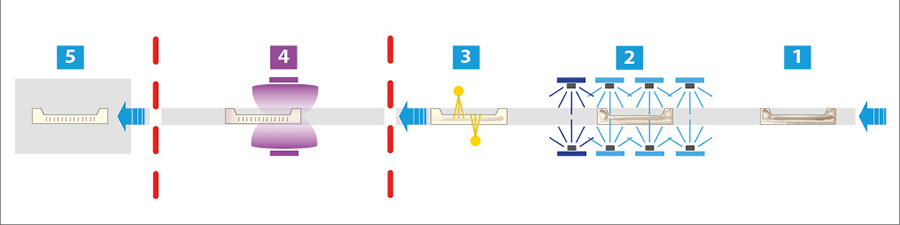

LAV10 with tunnel for uv lamps treatment:

- TRAYS ENTRY

- PRESSURE WASH WITH WATER FROM THE TANK + RINSE WITH CURRENT WATER

- TRAYS DRAINAGE

- TREATMENT WITH UV LAMPS

- EXIT TABLE FOR WATER DRAINING

VIDEO1 - LAV10

VIDEO2 - WASHING LINE:

tray washer equipped with Feeding belt for single trays; pressure washing unit with water; trays treatment tunnel with UV lamp system and final balance stacker.

Technical data

| M.U. | LAV10 | LAV10 E | |

|---|---|---|---|

| HOURLY PRODUCTION (max) | containers/hour | 600 | 500 |

| CONTAINERS DIMENSIONS (max) | mm | 600x400 | 750x500 |

| CONTAINERS HEIGHT (max) | mm | 150 | 150 |

| WATER PUMP POWER | kW | 3,7 | 3,7 |

| WASHING PRESSURE | bar | (up to) 9 | (up to) 9 |

| INSTALLED POWER | kW | 5 | 5 |

| WATER TANK CAPACITY | l | 150 | 150 |

| WATER COMSUPTION | l/min | 8-10 | 8-10 |

| WASHING NOZZLES | n | 28 | 28 |

| RINSING NOZZLES | n | 10 | 10 |

| WEIGHT (standard version) | kg | 450 | 450 |