AUTOMATIC DESTACKER

ND

Automatic destackers

WITH MODULAR COMPOSITION – automatic destackers, for trays, pots and shuttle trays

MACHINE DESCRIPTION - EAC

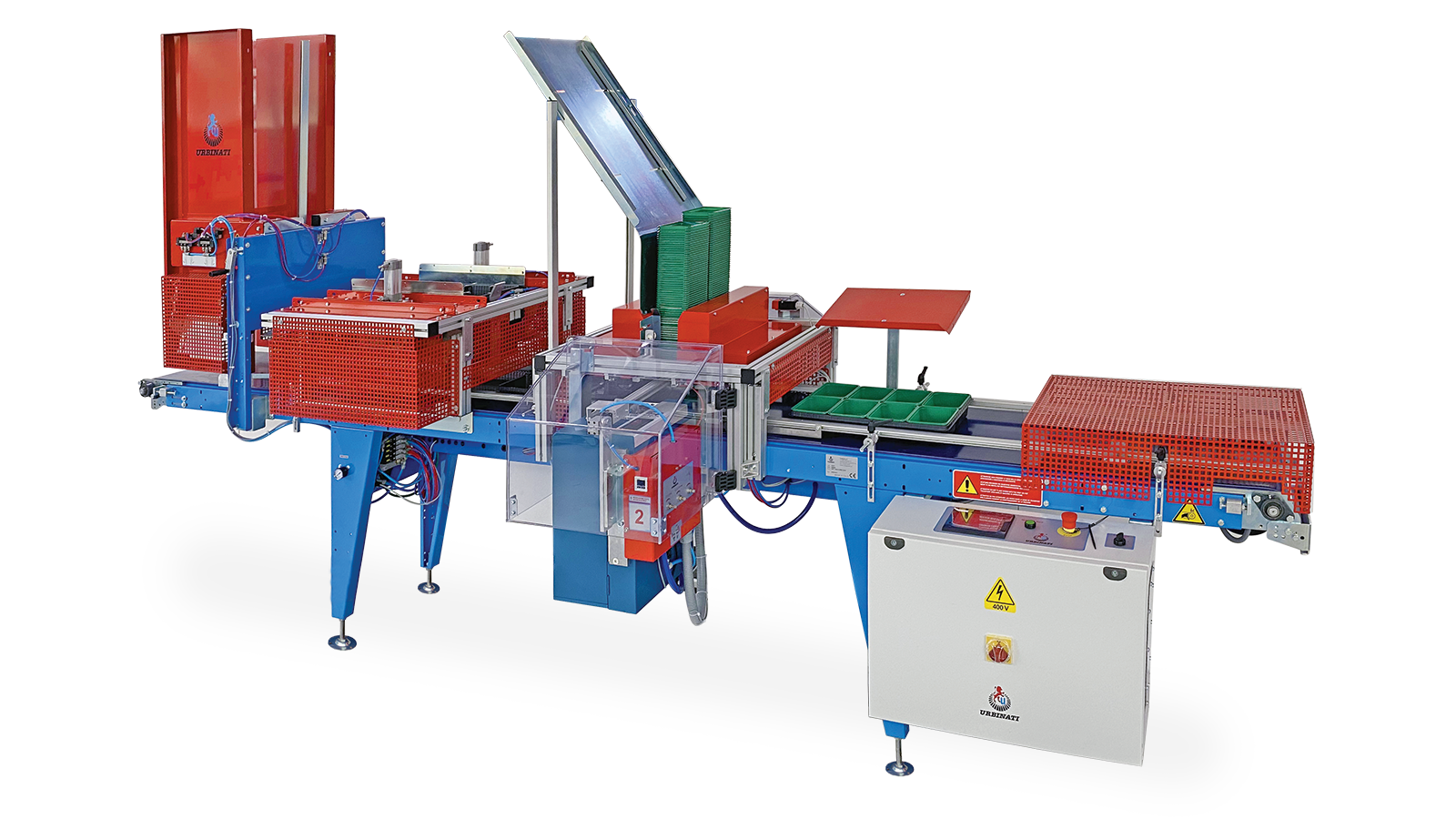

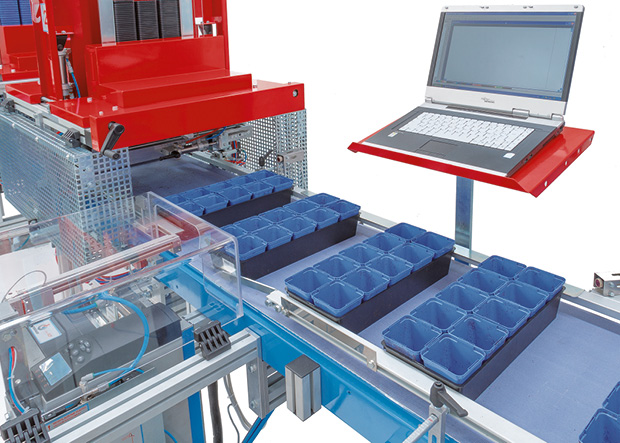

Electropneumatic machine with modular composition for stacking trays, tray-holders, pots, pot-holders and any type of container in general.

The automatic destacker is managed by PLC with touch-screen panel and it is possible to set up to 6 different destackers on the same machine. Each destacker can be managed independently and used simultaneously with all the others present or only with some of them.

Combined with the EAC labellers, the ND automatic destacker is ideal for managing and preparing containers before their will be use in any working line.

TECHNICAL SPECIFICATIONS - ND

- Machine managed with PLC and data display on touch-screen panel. Modular from 1 to 6 distributors.

- Available belt width: L = 450 / 600 mm.

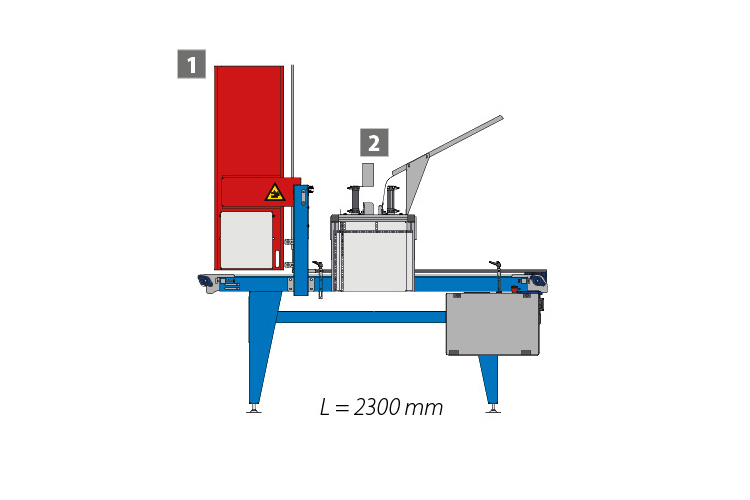

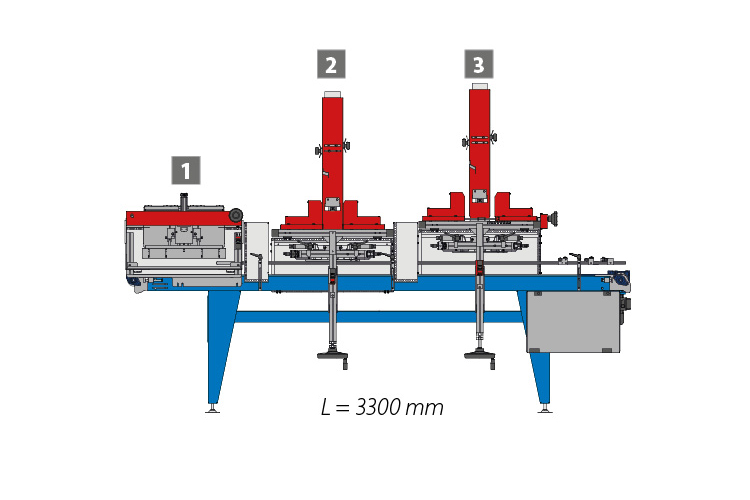

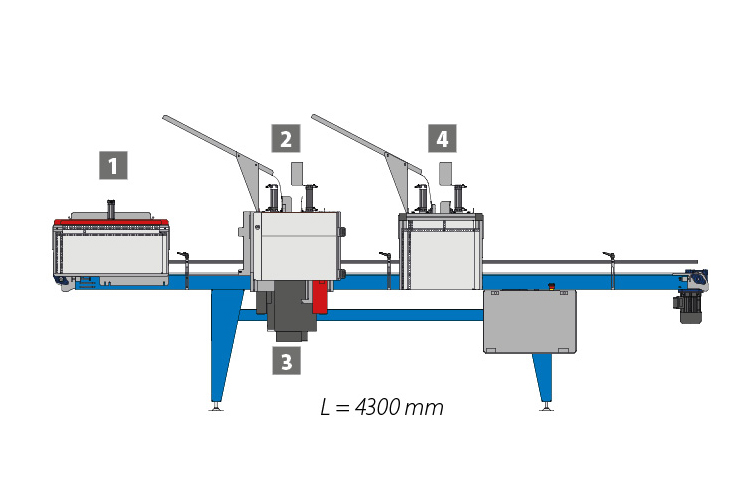

- Available belt lengths: L = 1300/2300/3300/4300/5300/6300 mm.

- Fixed-speed conveyor belt.

- Container presence detection with photocell and/or laser.

- Hourly production: based on the final configuration required.

- Available in right or left side operator version.

DETAILS / MAIN ACCESSORIES - ND

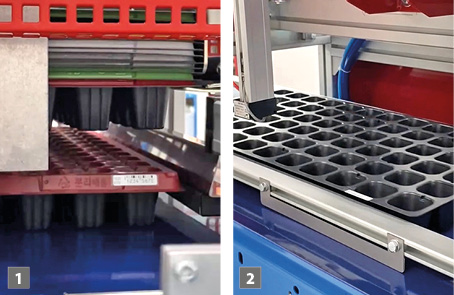

- 2 / 3 / 4-movements destackers, for tray, pots and containers in general, in all over shapes and sizes available on the market.

- 2-movement destacker with front or side loading.

- 3-movements destacker for barquette.

- Destacker for godet.

- EAC labelling machine, front and/or side.

- Empty trays stacks feeding belt.

- Stacking unit: balance stacker.

- Variable conveyor belt speed.

- Wheels kit for handling.

VIDEO1 - ND

VIDEO2 - ND

VIDEO3 - ND

VIDEO4 - ND

…