MACHINE DESCRIPTION - KAPPA65C

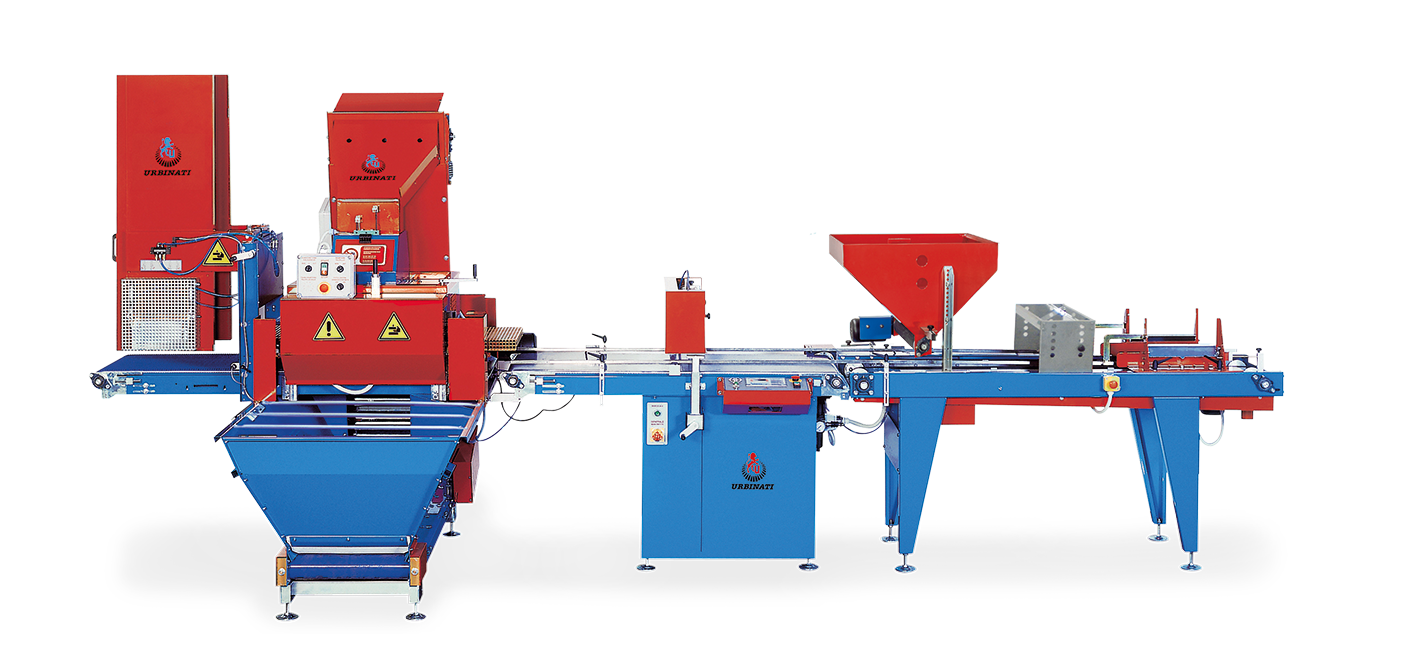

The KAPPA65 row seeding line is a modular line ideal for medium/small productions, capable of seeding up to 2400 rows/hour (120 containers/hour for a 200-cells container).

It is suitable for all types of trays: polystyrene, thermoformed and rigid injection molded plastic. Depending on the type used, a distributor is available that allows the automatic insertion of empty containers in the line.

The tray filler guarantees excellent coverage uniformity for all the cells and the ability to adjust the final density of the soil.

In the SEMKAPPA65 compact seeder the containers advance on a PVC conveyor belt and the electronically-synchronised seeding mechanism is operated by a seeding bar that suctions the seed and deposits it in a precise and homogeneous way in the cells, row by row In the same process, a hole is also made in which the seed is accurately placed in the centre of the cell and at the correct depth.

The main feature of the SEMKAPPA65 is its flexibility, with the possibility of quickly changing over the seeding nozzles and adapting the machine to the type of seed. Thanks to this feature, the KAPPA65C line is able to adapt, without additional costs, to any type of seed from the smallest to the largest.

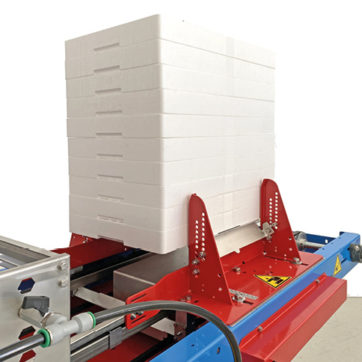

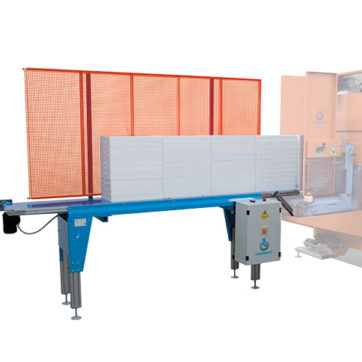

Finally, the covering and watering unit complete the seeding cycle, while the stacking unit, with the balance stacker, sorts the newly seeded containers in orderly stacks to make it easier to extract or palletise them.

Each component of the machine is designed and built according to the customer’s needs, to improve the work of the operators, to reduce maintenance and speed up seed change operations.

TECHNICAL SPECIFICATIONS - KAPPA65C

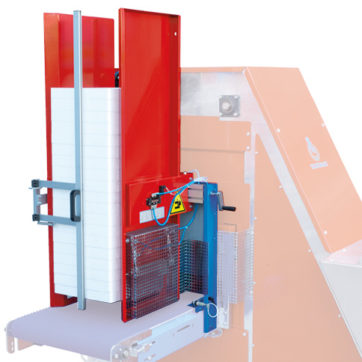

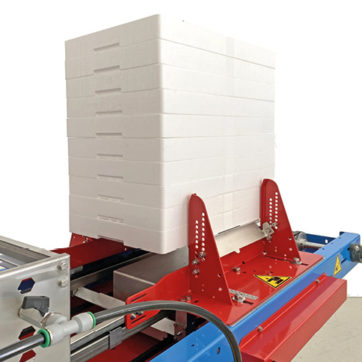

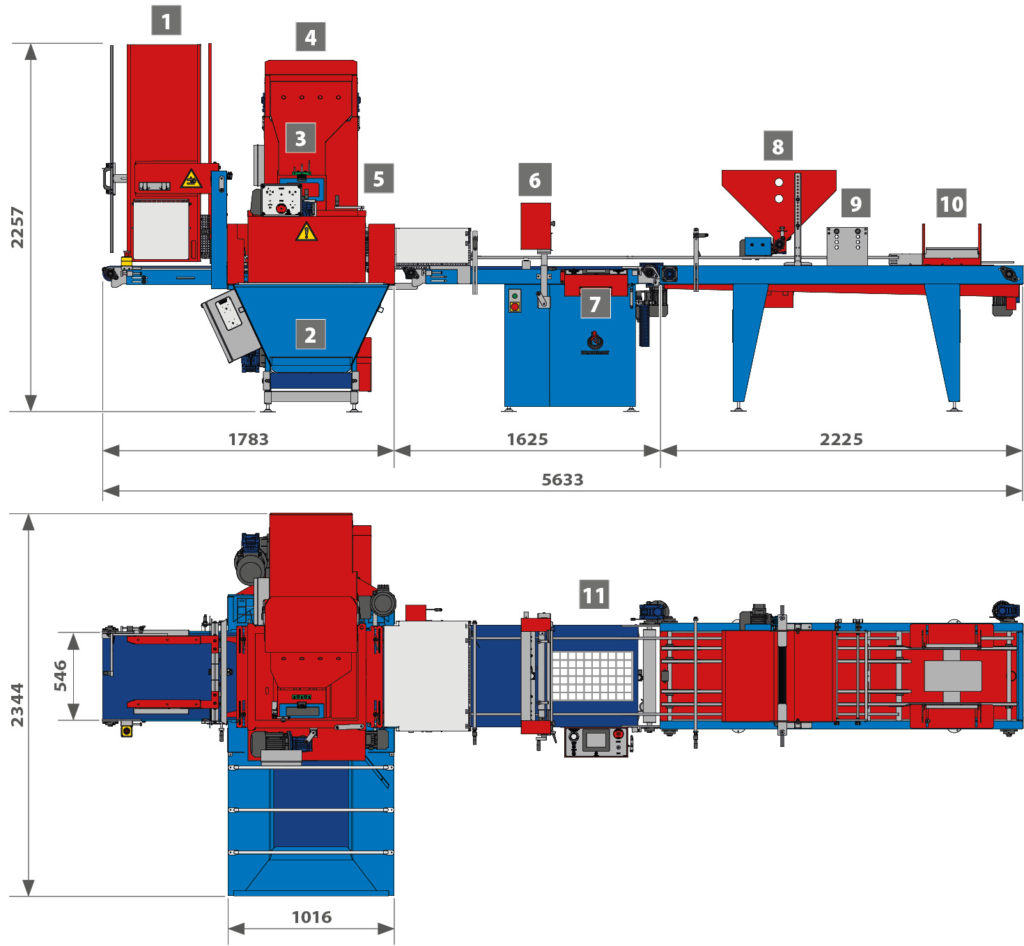

- 2-movements pneumatic tray destacker for polystyrene trays.

- Hopper capacity 700 litres. Conveyor belt with rollers on hopper’s bottom.

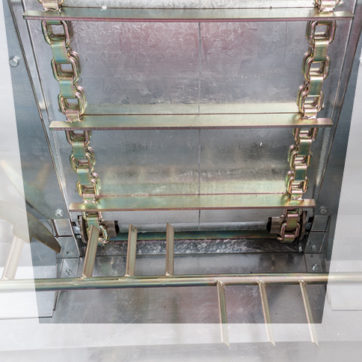

- Double chain soil elevator, width = 500 mm.

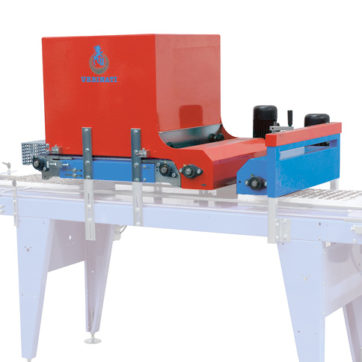

- Tray filler with 4 blades longitudinal rotor, with rotation reversing gear.

- Double auger spillway with motorized brush for tray cleaning.

- Automatic pitch seeding head, dibbling device included.

- Control panel with 5.7” colour touch-screen.

- Covering unit for vermiculite, with adjustable speed and dosage; capacity 100 litres.

- Watering unit with drilled bars module: length 250 mm with 1 bar.

- Stacking unit, with balance stacker.

- Longitudinal tray advancement.

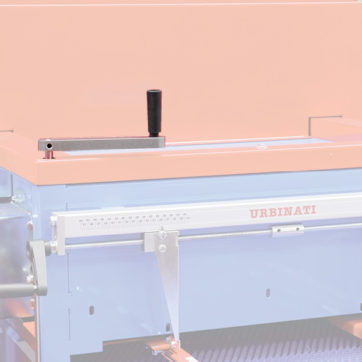

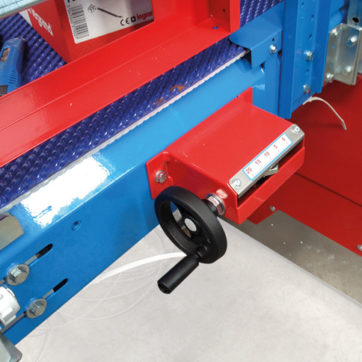

- Quick self-centring guide adjustment system.

- Available in left and right version.

VIDEO - KAPPA65C

TECHNICAL DATA

| M.U. | KAPPA65C | KAPPA65C E | |

|---|---|---|---|

| HOURLY PRODUCTION (max) | rows/hour | 2400 | 2400 |

| TRAYS DIMENSIONS (max) | mm | 750x400 | 750x500 |

| INSTALLED POWER | kW | 4,5 | 4,5 |

| VACUUM PUMP Venturi System | model | M20 | M20 |

| AIR CONSUMPTION (max) | l/min | 290 | 290 |

| WATER CONSUMPTION AT 2 atm (max) | l/min | 20 | 20 |

| WEIGHT | kg | 980 | 980 |