MACHINE DESCRIPTION - BETA65C

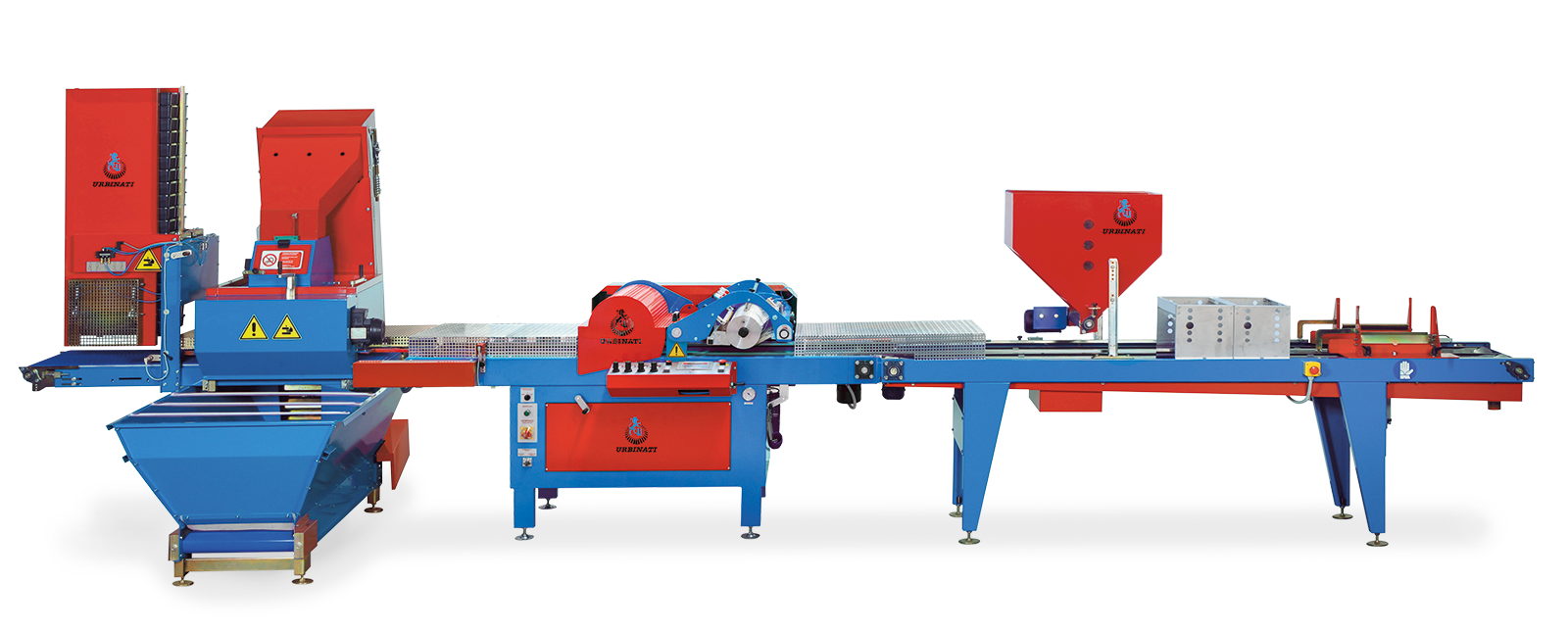

The BETA65 and BETA65C drum seeding lines are modular lines capable of sowing up to 800 containers per hour. These lines are suitable for all types of trays: polystyrene, thermoformed and rigid injection-molded plastic; Furthermore, depending on the used type, a dedicated dispenser is available that allows the automatic insertion of empty containers in the line.

The filler of these lines guarantees excellent coverage uniformity for all the cells, with the possibility of adjusting the final density of the soil; it also has an additional hopper for the automatic recovery of excess peat.

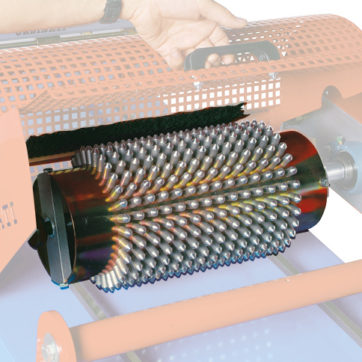

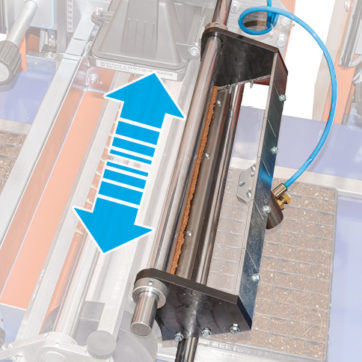

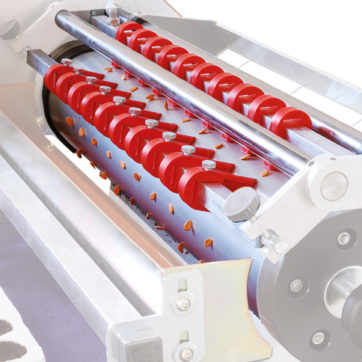

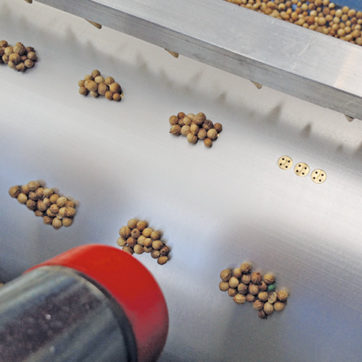

The heart of the machine is in the SEMBETA65 seeder: the containers in output from the tray filler first pass under a dibbler drum that allows the creation of a central and homogeneous hole for each cell in which the seed will then be placed. In the next phase, the seeds are positioned in the hole, in a precise and uniform manner, thanks to a dedicated sowing drum that picks them up and distributes them.

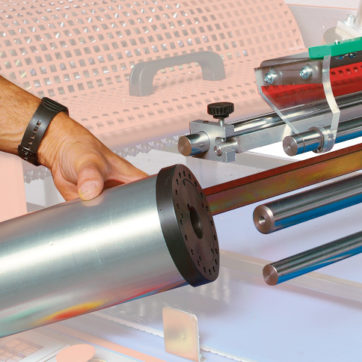

And here lies the remarkable flexibility of Urbinati machines: the incomparable suction power of the sowing drum allows it to work with all types of seeds, regardless of their shape and size.

The BETA seeding line can also be adapted to forest varieties and is capable of sowing large seeds, such as acorns, using a special rubber drum.

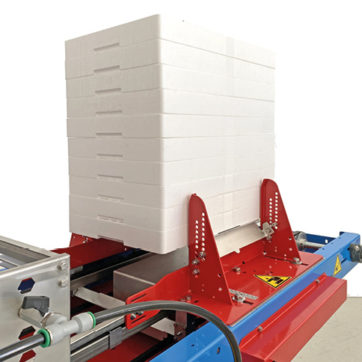

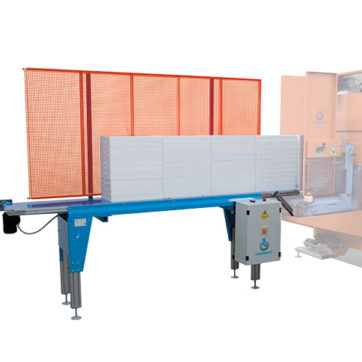

Lastly, the covering and watering unit complete the seeding cycle, while the stacking unit, with the balance stacker, sorts the newly seeded containers in orderly stacks to make it easier to extract or palletise them.

Each component of the machine is designed and built according to the customer’s needs, to improve the work of the operators, to reduce maintenance and speed up seed change operations.

TECHNICAL SPECIFICATIONS - BETA65C

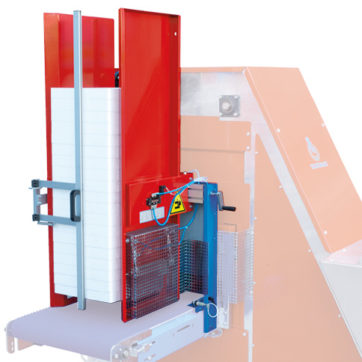

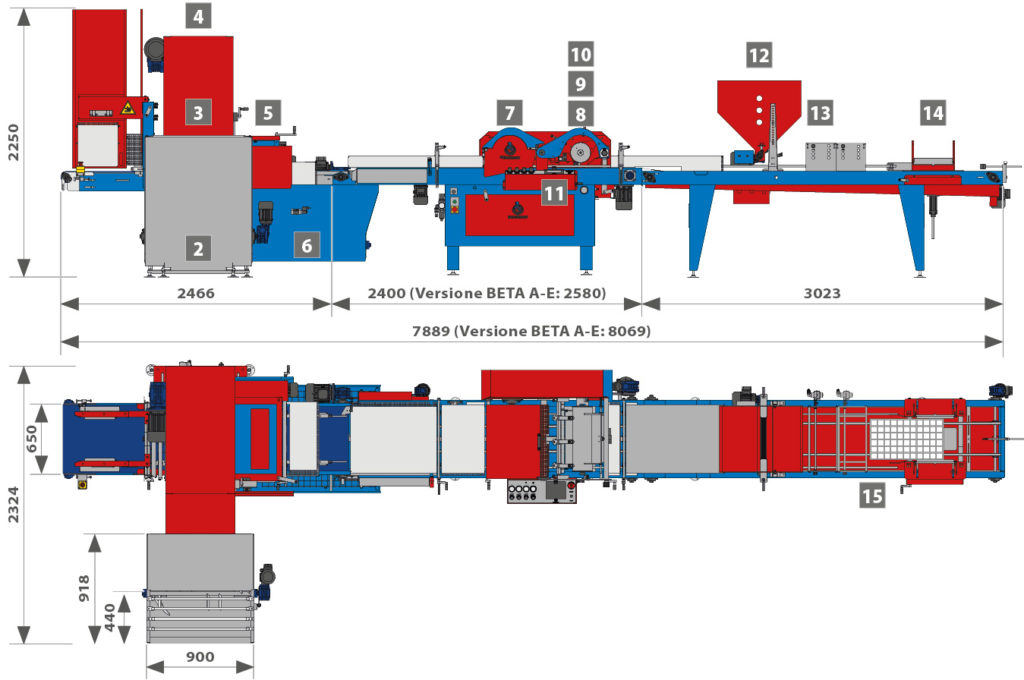

- 2-movements pneumatic tray destacker for polystyrene trays.

- Hopper capacity 700 litres. Conveyor belt with rollers on hopper’s bottom.

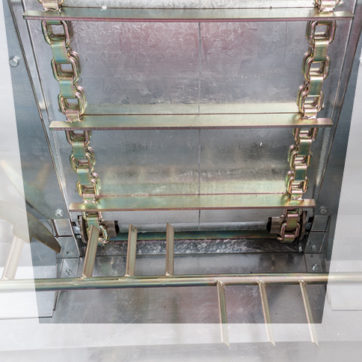

- Double chain soil elevator, width 500 mm.

- Tray filler with 4 blades longitudinal rotor, with rotation reversing gear.

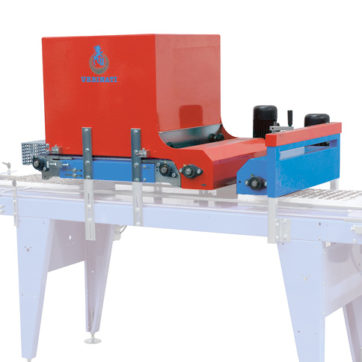

- Double auger spillway with motorized brush for tray cleaning.

- N.P.

- Dibbler drum with cleaning brush.

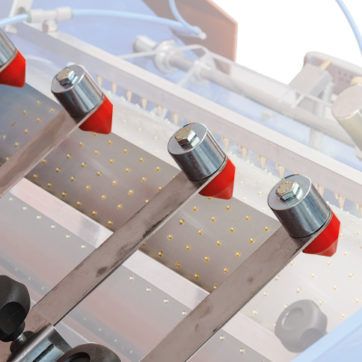

- Sowing drum with brass inserts: the inserts allow the creation of precise holes starting from 0.15 mm in diameter.

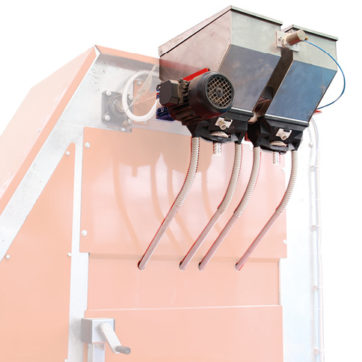

- Air bars with double row of nozzles and oscillating seed holding plate.

- Adjustable speed hammers to improve the singularization and positioning of the seed in the center of the hole.

- Control panel with 5.7” colour touch-screen.

- Covering unit for vermiculite, with adjustable speed and dosage; capacity 170 litres.

- Watering unit with drilled bars modules: length 750 mm with 3 bars.

- Stacking unit, with balance stacker.

- Longitudinal tray advancement.

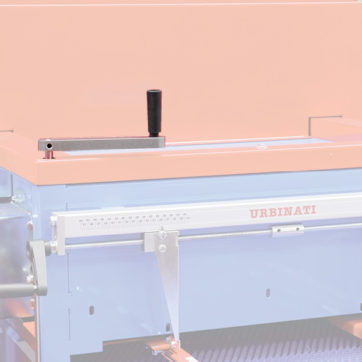

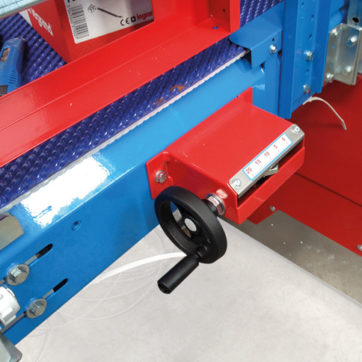

- Quick self-centring guide adjustment system.

- Available in left and right version.

(BETA65 layout)

VIDEO - BETA65C

TECHNICAL DATA

| M.U. | BETA65C | BETA65C A | BETA65C E | |

|---|---|---|---|---|

| HOURLY PRODUCTION (max) | trays/hour | 800 | 700 | 700 |

| TRAYS DIMENSIONS (max) | mm | 600x400 | 750x400 | 750x500 |

| INSTALLED POWER | kW | 7,5 | 7,5 | 7,5 |

| POMPA A VUOTO | model | PVA 1300 | PVA 1300 | PVA 1300 |

| AIR CONSUMPTION (max) | l/min | 190 | 190 | 190 |

| WATER CONSUMPTION AT 2 atm (max) | l/min | 20 | 20 | 20 |

| WEIGHT | kg | 1420 | 1420 | 1420 |