AUTOMATIC SEEDLING PLUG POPPER

ESTREA

AUTOMATIC OPERATION – up to 1.000 trays/hour

MACHINE DESCRIPTION - ESTREA

The ESTREA automatic plug depopper makes it easier to remove the seedling from the tray.

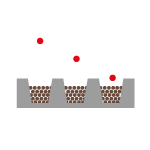

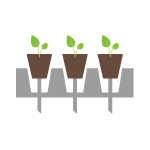

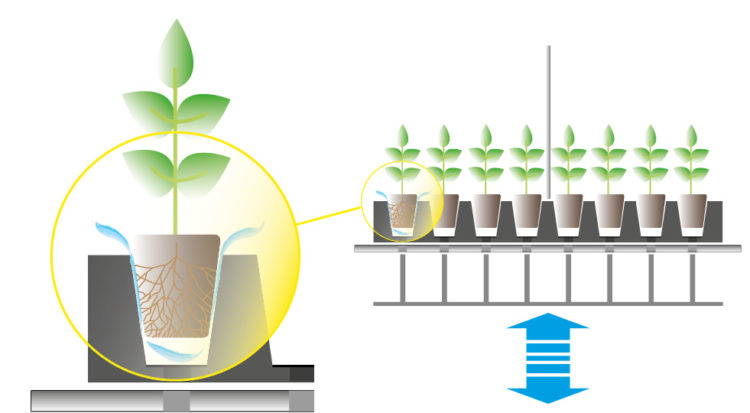

The depopper plate pins push from the bottom upwards directly on individual plants, eliminating friction with the sides of the container. The seedling is extracted with the plug intact, avoiding damage to the stem and roots. Once extracted, it can be more easily transplanted by hand into another container or used directly with automatic transplanters in the open field, as in the case of vegetables.

Extraction of the seedling from the cell during its development cycle also encourages the growth of a thick network of roots that will ensure the quality and health of the plant once transplanted.

The ESTREA electro-pneumatic plug depopper works continuously with any type of container, with a feed system on cross-bars and automatic positioning with respect to the plate.

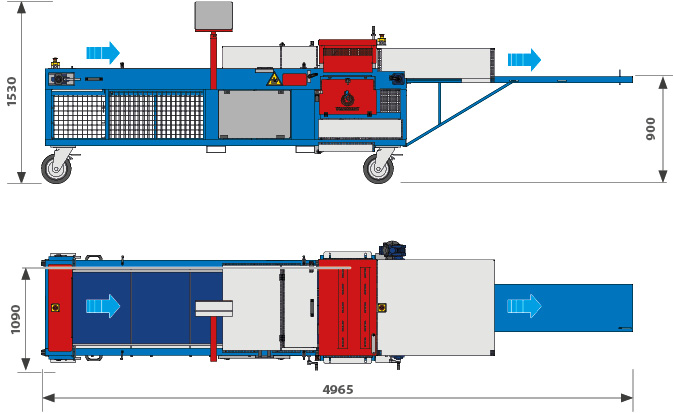

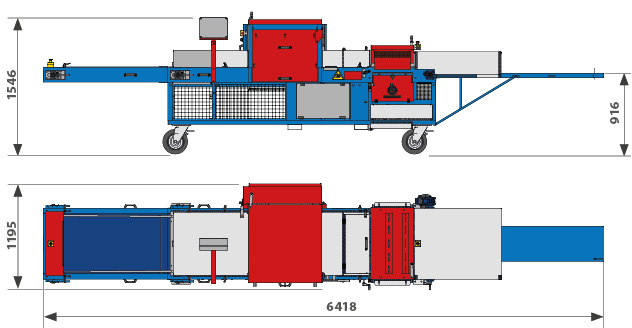

TECHNICAL SPECIFICATIONS - ESTREA

- Advancement with cross bars and electronic positioning of the tray.

- Self-centering depopper plate and rapid replacement from one side of the machine.

- Control panel with PLC, frequency drive and turning control board.

- Display of machine status, diagnostics and functions in automatic and manual.

- 5.7” monochrome touch screen panel.

- Removable exit table.

- Wheels kit for handling.

DETAILS / MAIN ACCESSORIES - ESTREA

- Self-centering depopper plate and counterplate.

- Trimmer with rotating blades.

- Drum with knives.

- Forestry version.

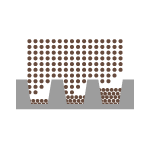

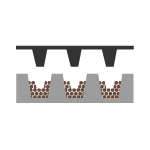

NOT EXTRACTED PLUG (sx): the limited availability of oxygen affects root development.

EXTRACTED PLUG (dx): oxygenation of the plug encourages dense root development.

VIDEO - ESTREA with CIMA

Technical data

| M.U. | ESTREA | |

|---|---|---|

| HOURLY PRODUCTION (max) | trays/hour | 1000 |

| TRAYS DIMENSIONS (max) | mm | 600x400 |

| PLATE PUSHING POWER | kg | 550 |

| INSTALLED POWER | kW | 2 |

| WEIGHT | kg | 390 |